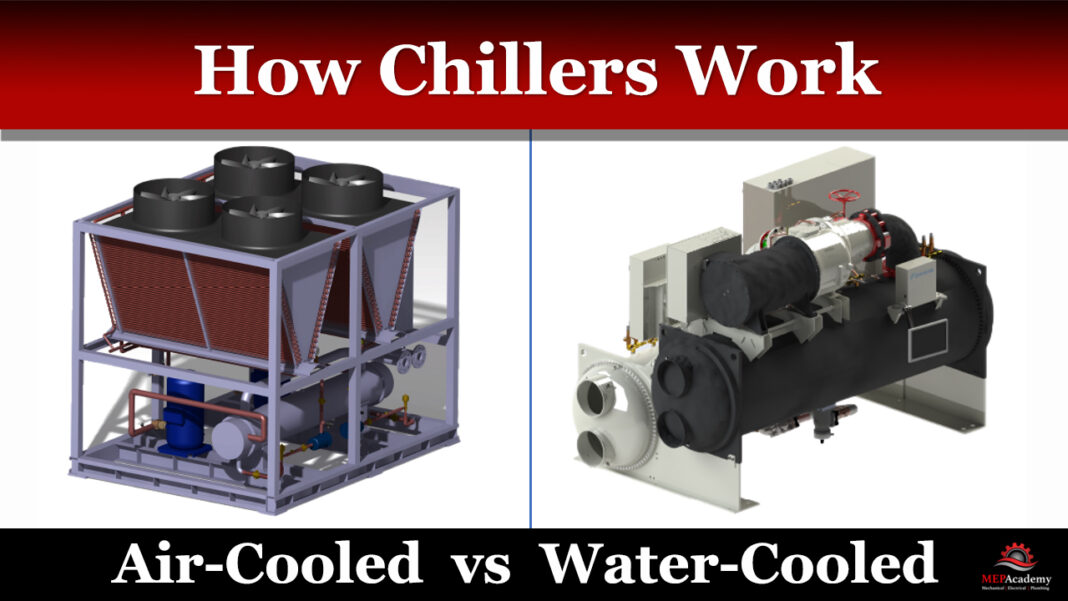

Air Cooled Vs Water Cooled Chillers And How They Workођ In this video we learn how air cooled and water cooled chillers work with air handling units to cool buildings. we learn the advantages and disadvantages of. Capacity: packaged air cooled chillers are typically available in sizes ranging from 7.5 to 500 tons [25 to 1,580 kw]. packaged water cooled chillers are typically available from 10 to 4,000 tons [35 to 14,000 kw]. in other words, water cooled chillers can deliver higher cooling capacity with fewer units and a smaller footprint.

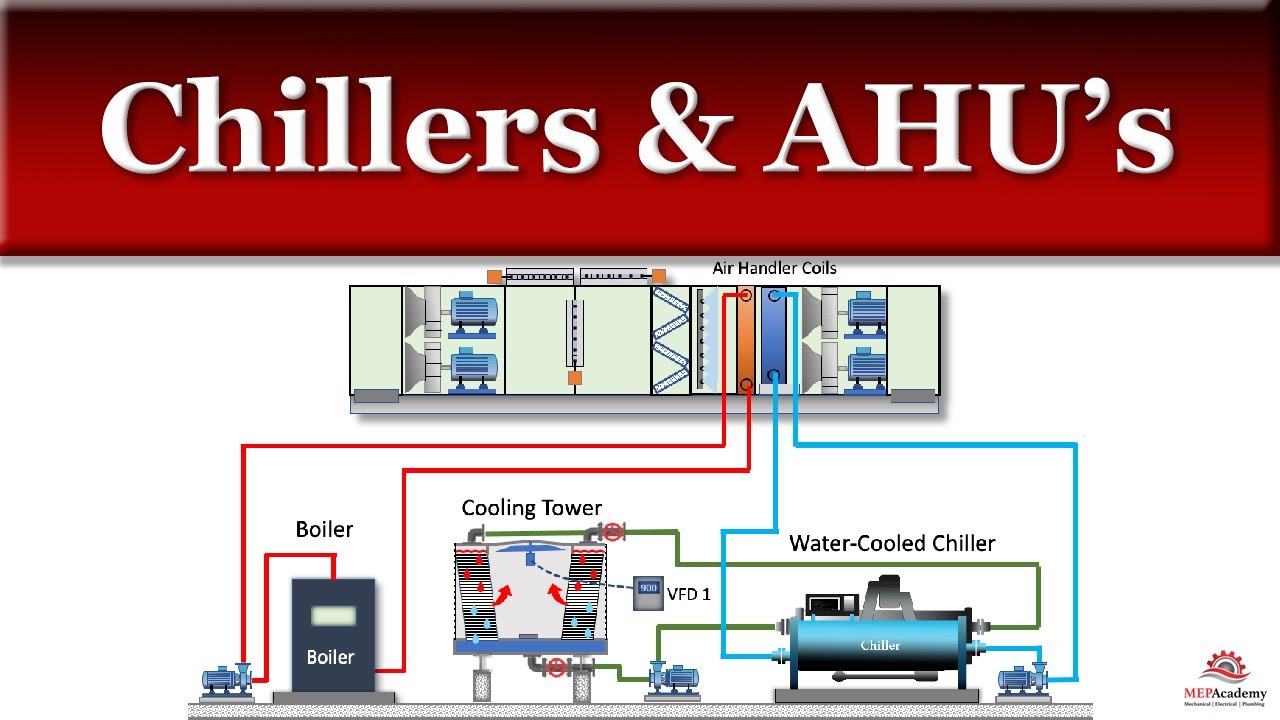

How Chillers Work Water Vs Air Cooled Chillers Mep Academy By comparison, water cooled chillers are more efficient than air cooled variants. air cooled chiller efficiency is dependent on the temperature of the ambient air being used in its cooling system. the higher the circulating cooling air temperature, the less efficiently an air cooled chiller will perform. The trade offs: they generally have shorter lifespans, require a large, open, outdoor space with continuous access to fresh air, are loud and are less efficient than water cooled chillers. air cooled chillers should be used only in areas where heat discharge does not pose a danger to the surrounding environment. Outdoor air cooled chiller package . both air cooled and water cooled chillers are viable options for industrial cooling applications, each with its own set of advantages and considerations. the choice between the two depends on the specific industrial requirements. Ground floor installed water cooled chiller serving air handling units. water cooled chillers are mostly installed indoors. this is one of the factors that leads to a longer equipment life, in the range of 20 to 30 years, as compared to an air cooled chiller which spends all of its life outdoors and operates at a higher condenser fluid temperature.

Air Cooled Vs Water Cooled Chillers Youtube Outdoor air cooled chiller package . both air cooled and water cooled chillers are viable options for industrial cooling applications, each with its own set of advantages and considerations. the choice between the two depends on the specific industrial requirements. Ground floor installed water cooled chiller serving air handling units. water cooled chillers are mostly installed indoors. this is one of the factors that leads to a longer equipment life, in the range of 20 to 30 years, as compared to an air cooled chiller which spends all of its life outdoors and operates at a higher condenser fluid temperature. The chilled water enters the ahu fcu and passes through the cooling coil (a series of thin pipes) where it will absorb the heat of the air blowing across. the chilled water heats up and the air blowing across it cools down. when the chilled water leaves the cooling coil it will now be warmer at around 12°c (53.6°f). Cost – many air cooled chillers are part of an easy to install packaged system that includes the condenser, compressor, and evaporator. quicker installation and fewer components translate to lower upfront and maintenance costs. energy efficiency – while water cooled chillers are best known for their energy efficiency, air cooled units.

Air Cooled And Water Cooled Chillers Explained The Engineering Mindset The chilled water enters the ahu fcu and passes through the cooling coil (a series of thin pipes) where it will absorb the heat of the air blowing across. the chilled water heats up and the air blowing across it cools down. when the chilled water leaves the cooling coil it will now be warmer at around 12°c (53.6°f). Cost – many air cooled chillers are part of an easy to install packaged system that includes the condenser, compressor, and evaporator. quicker installation and fewer components translate to lower upfront and maintenance costs. energy efficiency – while water cooled chillers are best known for their energy efficiency, air cooled units.

Comments are closed.