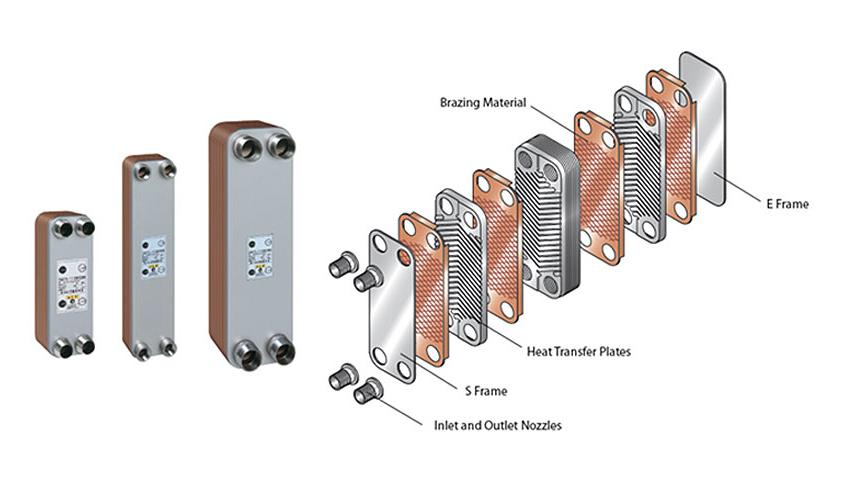

Hisaka Brazed Heat Exchanger Hesco Heat exchanger division at hisaka contributes the achievement of "energy saving, space saving, and highly efficient operation" for our customers' plants and equipment, through the manufacture and sales of plate heat exchangers for heating and cooling fluids, which is essential for any industrial process. High performance, small footprint, light, and durability make hisaka brazed plate heat exchangers suitable for limited space applications. even with a simpler structure, hisaka bhe has its own unique features to apply to various applications ensuring efficient thermal performance and reliability.

.png)

Brazed Plate Heat Exchangers Brazed Phe Hisakaworks This animation video showcases the working principle of hisaka’s brazed plate heat exchanger. the animation will help to illustrate how the plates work toget. Hisaka yx series plate heat exchanger is innovatively designed to improve the efficiency of your condenser. our yx series plate heat exchangers are widely used in beer processing plants, bioethanol plants, and sugar refineries. with its special yx plate pattern, yx series is compact, light, and can be easily installed. For heat exchanger design & calculations. q1 = density x heat capacity x ( 1 2 ) x 3 3600 [kw] q2 = density x heat capacity x ( 5 4 ) x 6 3600 [kw] (for water, density is 1000, and heat capacity is 4.186kj kg deg.c.) the heat duty on hot side (q1) is equal to the heat duty on cold side (q2); q1 and q2 must be the same (q1 = q2). You can disassemble the heat exchanger and increase or decrease the number of plates, or change the plate arrangement to change the heat transfer area and performance. bhe high pressure heat resistance since the contact areas between the heat transfer plates are brazed with nickel or copper, they can withstand high pressure and temperature. compact.

Hisaka Brazed Heat Exchanger Hesco Vrogue Co For heat exchanger design & calculations. q1 = density x heat capacity x ( 1 2 ) x 3 3600 [kw] q2 = density x heat capacity x ( 5 4 ) x 6 3600 [kw] (for water, density is 1000, and heat capacity is 4.186kj kg deg.c.) the heat duty on hot side (q1) is equal to the heat duty on cold side (q2); q1 and q2 must be the same (q1 = q2). You can disassemble the heat exchanger and increase or decrease the number of plates, or change the plate arrangement to change the heat transfer area and performance. bhe high pressure heat resistance since the contact areas between the heat transfer plates are brazed with nickel or copper, they can withstand high pressure and temperature. compact. This animation video showcases the working principle of hisaka’s fully welded plate heat exchanger. the animation will help to illustrate how the plates work. The design of the double wall brazed plate heat exchanger prevents cross contamination of fluid streams if there is an internal leak within the unit. two stainless steel plate walls separate the fluid streams, with an air gap in between. in the event of a leak, the affected fluid will flow into the air gap and escape out of the heat exchanger,.

Hisaka Brazed Heat Exchanger Hesco Vrogue Co This animation video showcases the working principle of hisaka’s fully welded plate heat exchanger. the animation will help to illustrate how the plates work. The design of the double wall brazed plate heat exchanger prevents cross contamination of fluid streams if there is an internal leak within the unit. two stainless steel plate walls separate the fluid streams, with an air gap in between. in the event of a leak, the affected fluid will flow into the air gap and escape out of the heat exchanger,.

Comments are closed.