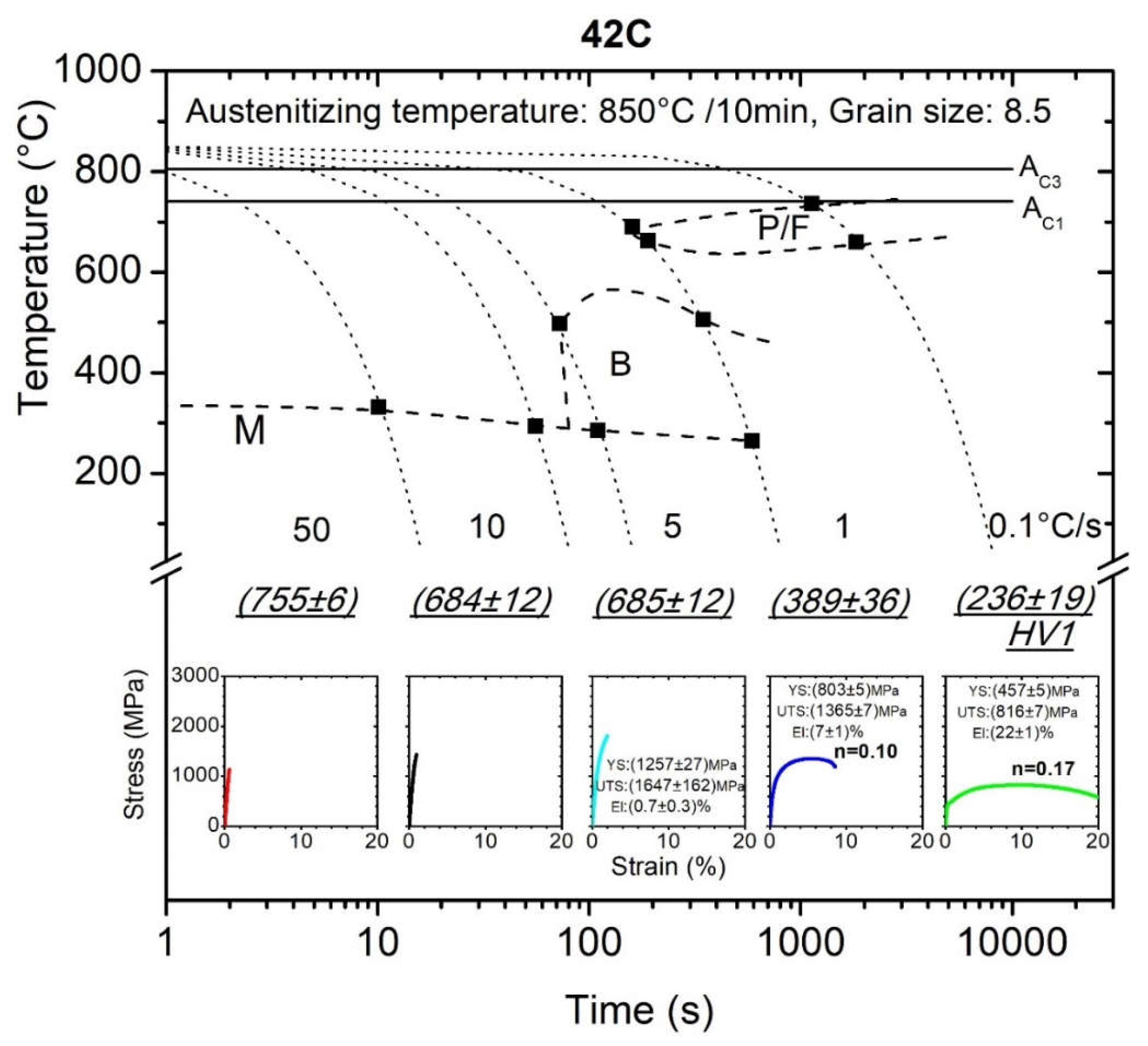

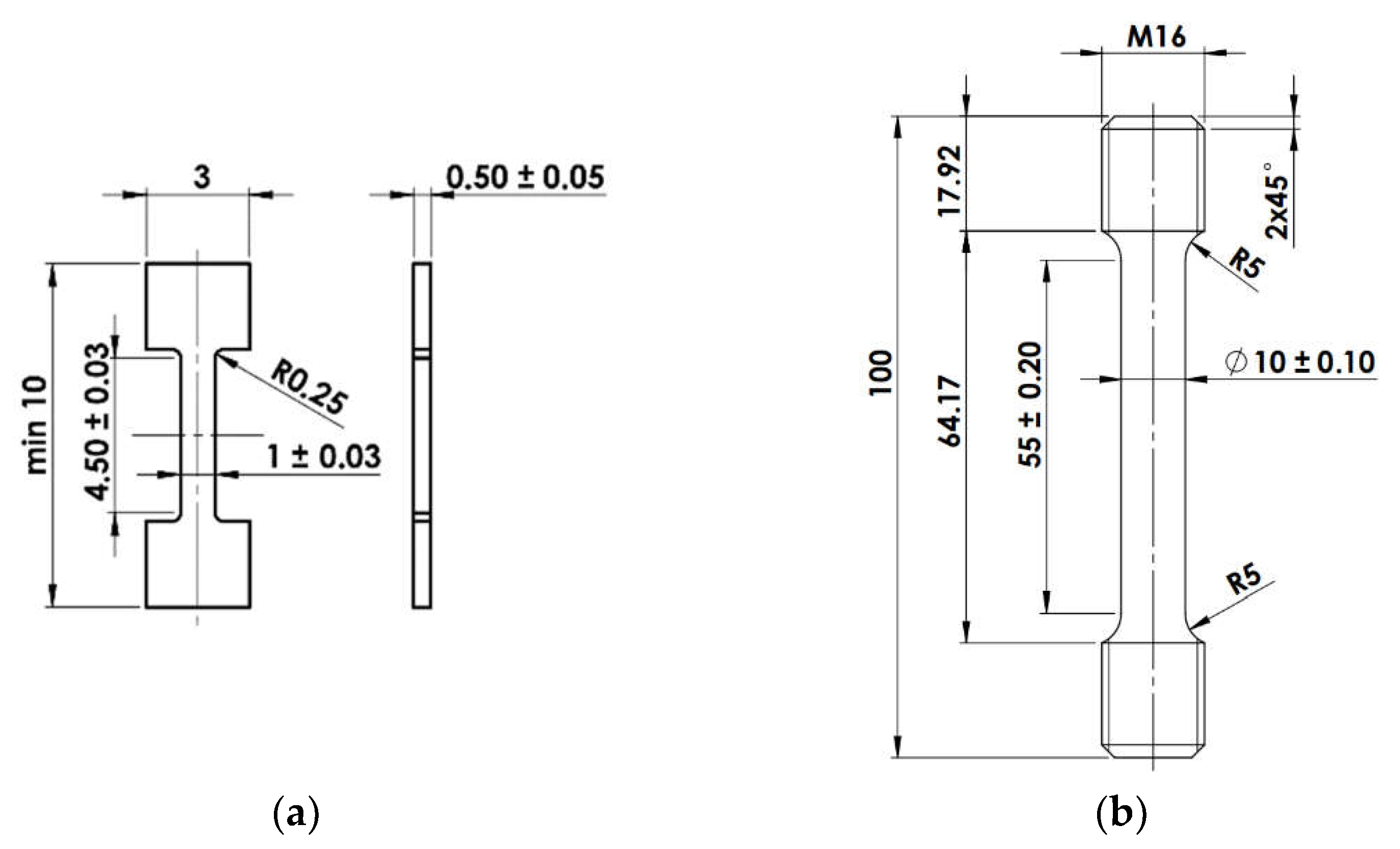

Materials Free Full Text Extended Continuous Cooling Transformation Continuous cooling transformation (cct) diagrams are widely used when heat treating steels and represent which type of phase will occur in a material as it is cooled at different cooling rates. cct diagrams are constructed on the basis of dilatometry measurements on relatively small testing samples (cylindrical shape with diameter of 4mm and length of 11 mm in this study). the main aim of this. Round 1. reviewer 1 report. the authors present a comparative study that investigates the cooling transformation characteristics of three kinds of steels processed by different treatment and their tensile properties and hardness, and as well try to argue that the mini tensile testing is an available alternative approach if the raw material lacks.

Materials Free Full Text Extended Continuous Cooling Transformation In this study, the phase transformation behaviour of the carburised layer and the matrix of 23crni3mo steel was comparatively investigated by constructing continuous cooling transformation (cct) diagram, determining the volume fraction of retained austenite (ra) and plotting dilatometric curves. the results indicated that austenite formation start temperature (ac1) and austenite formation. Continuous cooling transformation (cct) diagrams are widely used when heat treating steels and represent which type of phase will occur in a material as it is cooled at different cooling rates. Institute of technology, banaras hindu university. varanasi 221 005, india [email protected]. tata steel traerf faculty fellowship visiting scholar department of materials science and metallurgy university of cambridge, pembroke street, cambridge, cb2 3qz [email protected]. Continuous cooling transformation (cct) diagrams are widely used when heat treating steels and represent which type of phase will occur in a material as it is cooled at different cooling rates. cct diagrams are constructed on the basis of dilatometry measurements on relatively small testing samples (cylindrical shape with diameter of 4mm and length of 11 mm in this study). the main aim of this.

Comments are closed.